Electrical tape is one of the most versatile tools in electrical work and beyond. While its primary function is to insulate wires and prevent electrical hazards, its applications extend to bundling, labeling, sealing, and even creative DIY projects. In this comprehensive guide, we will explore the many ways electrical tape can be used, the different types available, and how to apply it properly for maximum efficiency.

Types of Electrical Tape

Understanding the different types of electrical tape available on the market will help you choose the right one for your specific needs:

- PVC Electrical Tape: The most common type, used for insulating electrical wires due to its flexibility, durability, and heat resistance.

- Rubber Electrical Tape: Known for its excellent insulating properties and resistance to moisture and chemicals, making it ideal for harsh environments.

- Cloth Electrical Tape: Used in the automotive industry and applications requiring high-temperature resistance and flexibility.

- Foil Electrical Tape: Designed for shielding applications, such as preventing electromagnetic interference (EMI) in data and telecommunication cables.

- High-Temperature Electrical Tape: Used in industrial applications where extreme heat resistance is required, ensuring long-term insulation and protection.

Importance of Electrical Tape in Electrical Work

Electrical tape plays a crucial role in maintaining safe and reliable electrical connections. Here’s why it is indispensable:

- Safety and Protection: Insulates wires to prevent accidental electrical shocks and short circuits.

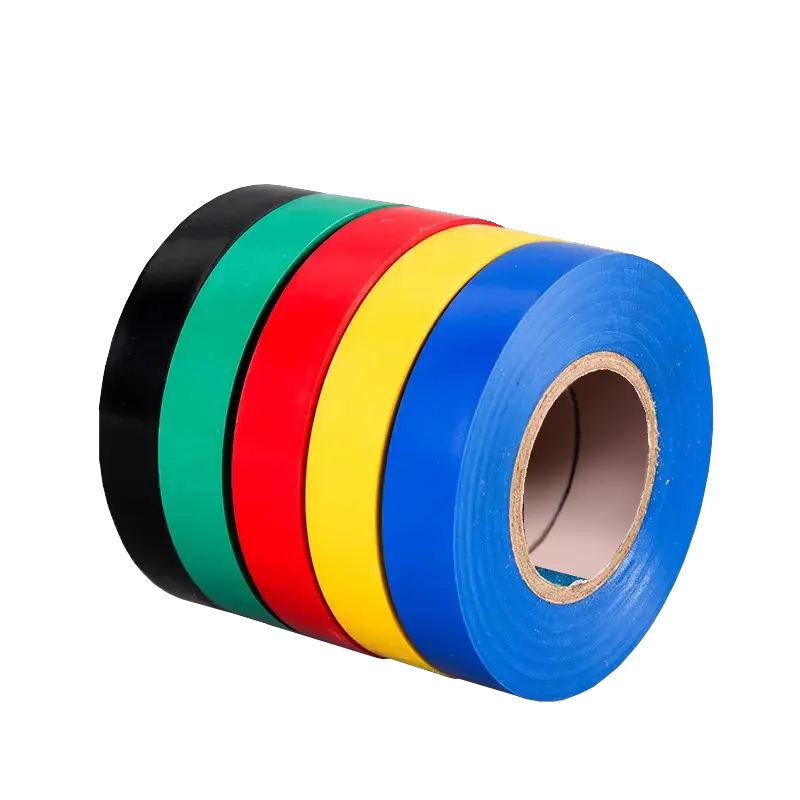

- Organization and Labeling: Different colored electrical tapes help distinguish between different voltage levels and circuits.

- Durability and Reliability: Protects electrical components from wear and tear, moisture, and environmental damage.

- Versatility: Used not only in electrical applications but also in automotive, HVAC, and telecommunications industries for bundling, repairs, and protection.

Proper Application Techniques for Electrical Tape

Applying electrical tape correctly ensures both functionality and safety. Follow these steps:

- Clean the Surface: Remove dust, moisture, or debris from the surface before application.

- Wrap in Layers: Start at the base and wrap in overlapping layers to create a strong insulation barrier.

- Avoid Gaps: Ensure each wrap overlaps the previous one by half of its width.

- Press Firmly: Secure the tape by pressing down to ensure proper adhesion.

- Use the Right Length: Avoid excessive tape usage that could cause it to peel or fray over time.

Common Mistakes to Avoid When Using Electrical Tape

To maximize the effectiveness of electrical tape, avoid these common mistakes:

- Inadequate Overlap: Leaving gaps can expose wires to hazards.

- Using the Wrong Type of Tape: Choose a tape that matches the temperature and environmental conditions of your application.

- Overstretching the Tape: Stretching too tightly may cause the tape to break or lose adhesion.

- Applying Insufficient Layers: Multiple layers provide better insulation, especially in high-voltage applications.

- Ignoring Manufacturer Guidelines: Always check the tape’s voltage and temperature ratings before use.

Creative Uses of Electrical Tape Beyond Electrical Work

Electrical tape is not limited to electrical applications. Here are some creative ways to use it:

- Automotive Repairs: Temporary fixes for cables and plastic components.

- Home DIY Projects: Organizing wires, securing fixtures, and labeling cables.

- Crafting and Decorating: Creating geometric patterns and custom art projects.

- Sports Equipment Repair: Securing hockey sticks, tennis rackets, and other gear.

- Emergency Fixes: Sealing small cracks, leaks, or broken handles until a permanent repair is made.

Safety Precautions When Working with Electrical Tape

Electrical tape enhances safety, but precautions must be taken:

- Use in Dry Conditions: Moisture can compromise insulation properties.

- Check Voltage Ratings: Ensure the tape is suitable for the voltage level of your project.

- Avoid High Heat Exposure: Use high-temperature-rated tape for extreme conditions.

- Wear Protective Gear: Use gloves and goggles when handling electrical systems.

- Dispose Properly: Used tape should be discarded safely to prevent hazards.

How to Choose the Right Electrical Tape

When selecting electrical tape, consider these factors:

- Temperature Resistance: For high-heat applications, choose heat-resistant tape.

- Voltage Rating: Select a tape that matches your electrical system’s voltage requirements.

- Durability: For outdoor use, opt for weather-resistant tape.

- Color and Size: Use different colors for labeling and organizing.

Maintenance and Storage Tips for Electrical Tape

Proper storage and maintenance can extend the life of your electrical tape:

- Store in a Cool, Dry Place: Heat and humidity can degrade the adhesive.

- Avoid Direct Sunlight: UV exposure can cause tape to fade and lose effectiveness.

- Seal Ends Properly: Prevent unraveling and dirt accumulation by sealing open rolls.

Conclusion: The Versatility and Value of Electrical Tape

Electrical tape is an essential tool in both professional and DIY settings. From ensuring safe electrical connections to facilitating repairs, organization, and creative projects, its applications are vast. By selecting the right type, applying it correctly, and following safety guidelines, you can make the most of this simple yet powerful tool. Whether you’re an electrician, technician, or DIY enthusiast, electrical tape is a must-have in your toolkit.

Products

Rich variety of adhesive tape