When it comes to industrial adhesives and sealants, butyl tape is a go-to solution, widely valued for its strong adhesion and weather resistance. In this article, we dive into the unique properties of butyl tape, its common applications, and how it can be used to provide reliable solutions for various commercial and industrial projects.

What Is Butyl Tape?

Butyl tape is a type of adhesive that belongs to the rubber-based family of sealants. Developed as an improvement over traditional rubber adhesives, butyl tape is known for its excellent bonding properties, especially in environments with moisture or fluctuating temperatures. Unlike other adhesives, butyl sealant tape maintains its stickiness at lower temperatures, making it a versatile choice for various commercial applications.

This highly flexible adhesive is ideal for bonding a wide range of surfaces such as metal, glass, wood, and plastic. It is commonly used in construction and outdoor industries for its strong and long-lasting adhesive properties, especially when applied in environments that require sealing against moisture.

Key Advantages of Butyl Tape

- High Adhesion Strength: Butyl tape offers superior bonding, even on surfaces that are resistant to other adhesives. This makes it a preferred choice for securing materials in harsh industrial environments.

- Weather Resistance: Whether working in hot, cold, or wet conditions, butyl tape maintains its adhesive strength, providing a reliable seal even under challenging weather.

- Flexibility: The tape is extremely flexible, allowing it to conform to various surface shapes and sizes, making it ideal for areas with irregular surfaces, like decking or roofing systems.

- Cost-Effective: Compared to silicone or acrylic adhesives, butyl tape offers excellent performance at a lower cost, making it a practical choice for businesses looking to stay within budget without sacrificing quality.

- Waterproof and Airtight: Butyl tape creates a reliable, watertight seal, which is essential in applications such as deck construction, roof sealing, and window installation.

Butyl Waterproof Tape

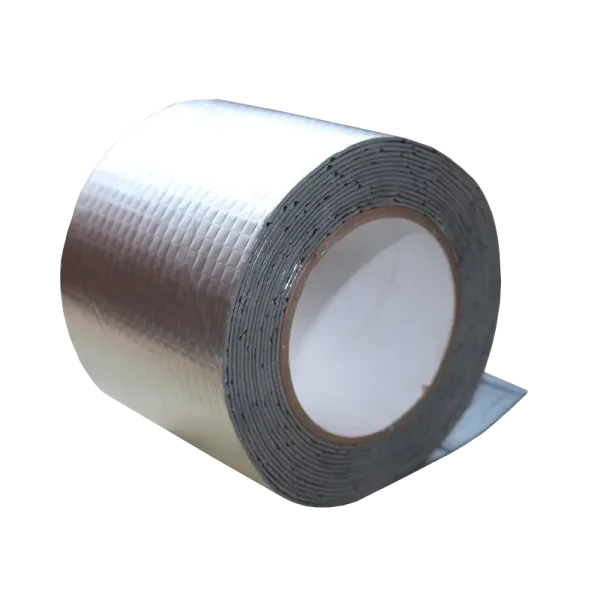

TXTAPE offers butyl waterproof tape designed to provide an effective solution for sealing and repairing leaks in buildings. Its high-quality rubber adhesive ensures strong, long-lasting performance in a variety of applications. Adhesive Rubber Adhesive Side Single Sided Adhesive Type Pressure Sensitive Design Printing No printing Material ALUMINIUM FOIL Feature Waterproof Use MASKING 🎁 Free sample application!Apply immediately

Common Uses of Butyl Tape in Industrial Applications

- Construction and Decking

In the construction industry, butyl tape is widely used to protect and seal decking structures. When applied to joists, beams, and ledger boards, it prevents water from seeping into the wood, thus extending the life of the deck and preventing rot. Deck flashing tape helps create a durable barrier, ensuring that moisture and condensation don’t penetrate the substructure, which could lead to expensive repairs down the line. - Roofing and Waterproofing

Butyl sealant tape is also highly effective in roofing applications. It is commonly used to seal seams, gaps, and flashing around roof edges. Due to its resistance to temperature extremes and moisture, it provides long-lasting protection for roofing materials, ensuring that water doesn’t penetrate the roofing system, thus preventing leaks and structural damage. - Automotive and RV Repairs

For industries dealing with RV maintenance or automotive repairs, butyl tape provides an easy, reliable way to seal joints, windows, and vents. It’s commonly used in RV butyl putty tape to seal gaps around windows and prevent moisture from entering the vehicle’s interior, ensuring better insulation and reducing the likelihood of mold or mildew growth. - Sealing HVAC Systems

Butyl tape is often used in HVAC systems for sealing ducts and pipes. Its ability to create airtight seals helps improve the efficiency of the system and prevents energy loss due to leaks.

Pros and Cons of Butyl Tape

Advantages:

- Strong Bonding: Butyl tape adheres well to even challenging surfaces like galvanized steel, glass, and metal.

- Temperature Tolerance: It performs reliably in both hot and cold conditions, making it ideal for use in extreme climates.

- Flexible and Durable: The tape’s flexibility allows it to adapt to irregular surfaces, while its durability ensures that it maintains its sealing properties over time.

- Affordable: In most cases, butyl tape is more affordable than alternatives like silicone and acrylic, offering businesses a cost-effective solution for sealing and bonding.

Disadvantages:

- Solvent Sensitivity: Being solvent-based, butyl tape can dissolve when exposed to strong solvents such as gasoline, turpentine, or mineral oils.

- Surface Sensitivity: It may not adhere well to very rough or porous surfaces, which could compromise the seal.

- Temperature Sensitivity: While it performs well under a wide range of temperatures, extreme heat or cold could reduce its effectiveness over time if not applied correctly.

- Not Suitable for Post-Construction Sealing: For sealing after the construction process, such as around window frames, caulking may be more effective.

Choosing the Best Butyl Tape for Your Needs

When purchasing butyl tape for industrial applications, there are a few key factors to consider:

- Ease of Installation: Choose a self-adhesive butyl tape that is easy to apply without requiring extensive cutting or overlap. The more straightforward it is to install, the quicker your team can complete the job.

- Durability and Warranty: Look for heavy-duty butyl tape that offers a strong warranty, ensuring that the product will last for years to come. For example, Trex Protect Joist & Beam Tape comes with a 25-year warranty, providing peace of mind that the tape will withstand the test of time.

- Cost Efficiency: While the upfront cost of butyl tape is important, consider the long-term savings that come from its durability and efficiency. A product with a solid warranty and reliable performance can offer better value than cheaper alternatives.

How to Properly Install Butyl Tape

To ensure the best performance, it’s crucial to apply butyl tape correctly. Here’s how to do it:

- Surface Preparation: Make sure the surface is clean, dry, and free of any debris that could affect adhesion.

- Apply the Tape: Remove the backing and apply the tape directly to the surface. Press it down firmly to ensure a secure bond.

- Cut to Fit: Use a utility knife or scissors to trim the tape to the desired length.

- Ensure Complete Coverage: Make sure the tape covers all necessary areas, such as joints, seams, or edges, to create a complete, airtight seal.

Conclusion

Butyl tape is a versatile and highly effective adhesive that offers long-lasting, waterproof, and weatherproof solutions for a wide range of industrial applications. Whether you’re sealing decking structures, roofing systems, or automotive repairs, butyl tape provides superior bonding and durability at an affordable cost. Choose the right butyl tape for your needs, and enjoy peace of mind knowing you’ve made a reliable investment in your commercial or industrial projects.

Products

Rich variety of adhesive tape