1️⃣ The Real Problem: Packaging Mistakes That Are Silently Killing Profit Margins

In the world of export e-commerce and warehouse logistics, packaging often gets treated as a minor operational detail — until it starts costing you money. And it always does.

Ask any warehouse manager or cross-border seller, and they’ll tell you:

- Packages bursting open during transit

- High customer return rates due to damaged or mishandled parcels

- Inconsistent packing speed that slows down the shipping line

- Wasted material from poor carton sizing or tape selection

- Rising labor costs due to inefficient packing practices

A 2024 report by Statista Logistics Insights found that 14% of cross-border parcels experience some form of packaging issue leading to damage claims or delayed deliveries, directly impacting customer retention and profitability.

And here’s the part most businesses underestimate — these packaging-related issues add up silently over thousands of orders, eroding your net profit month after month.

2️⃣ Common Market Problems: Why Most Packaging Systems Fail in Practice

While plenty of companies think they’re doing fine because they’re using bubble wrap and standard tapes, several overlooked factors quietly cripple logistics performance:

- Mismatch between carton size and product dimensions, leading to excessive filler use and higher shipping costs.

- Low-grade sealing tapes that lose adhesion in humidity or under pressure, causing open cartons and split packages.

- Inconsistent packing standards across teams or shifts, resulting in variable package quality.

- Lack of visual safety marking tapes in busy warehouses, increasing accident risks.

- Inefficient manual packing processes, especially during high season, causing bottlenecks.

A survey by Packaging World Magazine revealed that 68% of medium-sized warehouses still rely on outdated manual packing protocols without KPI-based optimization.

3️⃣ Data-Driven Solutions: How Smart Packaging Materials and SOPs Improve Bottom Lines

Here’s what’s actually working for modern warehouses and e-commerce brands:

✅ Right-Sized Cartons + Automated Box Selection Systems:

Firms using software-integrated cartonization systems reported a 17-25% reduction in filler materials and shipping volume costs.

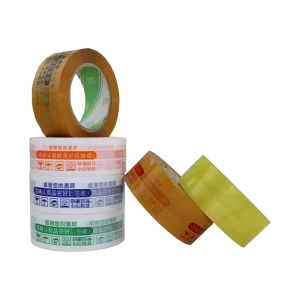

✅ High-Performance BOPP Tapes and PTFE High Temp Tapes:

Switching from generic OPP tapes to premium BOPP sealing tapes cuts package failure rates by over 50%. For heat-sealing applications, PTFE high temp tapes reduce maintenance and increase uptime by 30%.

✅ Color-Coded and Warning Tapes for Floor Marking:

Warehouses using clear visual marking systems experience a 40% drop in minor accidents and faster staff orientation for new hires.

✅ Standardized Packing SOPs and Staff Training:

Warehouses implementing strict packing standards with KPI tracking saw 20% faster throughput during peak periods.

✅ Supplier Consolidation and Bulk Order Planning:

Companies optimizing supplier networks for packing consumables reduced their annual packing material costs by 18-22% through consolidated, pre-planned purchasing cycles.

4️⃣ Case Example: How an Export Seller Reduced Packaging Costs by 28%

A mid-sized export e-commerce business in Guangzhou specializing in automotive parts faced constant issues with package damage and delays.

Problems they had:

- 10-15 burst cartons per week during international shipping

- Frequent adhesive failure in humid warehouse conditions

- Packing staff overtime during holiday sales

What they changed:

- Shifted to TXTAPE premium BOPP tapes (higher tensile strength, anti-split)

- Implemented color-coded floor marking and packing zones

- Trained packing staff to follow new SOPs

- Bulk-purchased packing consumables quarterly instead of monthly

Results after 90 days:

- Package damage rate dropped from 1.2% to 0.4%

- Packing speed improved by 18%

- Monthly packing material costs reduced by 28%

- Staff overtime cut by 35% during peak sales

5️⃣ Industry Trend Comparison: Old Habits vs Modern Practices

| Aspect | Traditional Warehousing | Modern Logistics Packaging |

|---|---|---|

| Tape Selection | Generic OPP tape | High-adhesion BOPP / PTFE |

| Packing SOPs | Unwritten, varied | KPI-tracked, enforced |

| Floor Safety Marking | Minimal, unstandardized | Color-coded system |

| Packing Speed | 50-60 parcels/hour | 70-85 parcels/hour |

| Package Failure Rate | 1.0-1.5% | 0.3-0.5% |

| Material Waste (fillers) | High (15-20%) | Low (5-10%) |

| Procurement Planning | Ad-hoc monthly buys | Consolidated quarterly deals |

6️⃣ FAQs: What B2B Buyers Are Asking

Q: Is switching to high-performance tapes worth the extra upfront cost?

A: Yes — typically, premium tapes reduce carton failures and rework labor, delivering a net cost saving within 30-60 days of implementation.

Q: How can we improve packing speed without automation?

A: Standardized packing SOPs, clear floor layouts using marking tapes, and bulk-ready packing stations increase speed by 15-25% without machines.

Q: Can we get custom tape sizes or printed tapes?

A: Yes — suppliers like TXTAPE offer custom BOPP tape sizes, colors, and logo prints even for mid-size order volumes.

Q: Are floor marking and warning tapes really necessary?

A: Factories and warehouses with visual management systems experience fewer accidents, faster staff orientation, and better audit results.

7️⃣ Why Partnering with Experienced Manufacturers Matters

Not all suppliers understand the operational challenges of modern logistics.

Brands like TXTAPE bring:

- 23 years of industrial packaging experience

- Daily capacity of 600,000+ rolls across 3 plants

- ISO9001 and export compliance for global shipments

- Custom product development for logistics, e-commerce, and cold chain industries

- Consistent supply and 7-day lead times, even in peak seasons

A cheap tape or filler roll might save a dollar now but lose you $100 in claims, delays, and bad reviews later. Working with tested, reliable suppliers removes one of the biggest hidden operational risks.

8️⃣ Limited-Time Offer: Free Packaging Audit + First Order Discount

From now until July 31, 2025, TXTAPE is offering:

🎁 Free packaging efficiency assessment for B2B clients

🎁 Free tape and marking samples for warehouse trial

🎁 Off your first consolidated bulk order

🎁 Guaranteed 7-day lead time for urgent logistics operations

Reach out now and discover how small changes in packaging materials and workflow can protect your profits and scale your shipping operation faster.

👉 [Apply for free sample] | [Get your audit today]

Products

Rich variety of adhesive tape